Best Steps for Accurizing your Rifle

- 360 Precision

- Insights

- Insights

- Best Steps for Accurizing your Rifle

Below are many of the most common steps that you can take to improve the accuracy of your rifle. Having a gunsmith perform the below steps will help improve your rifle’s accuracy and make you a better shooter.

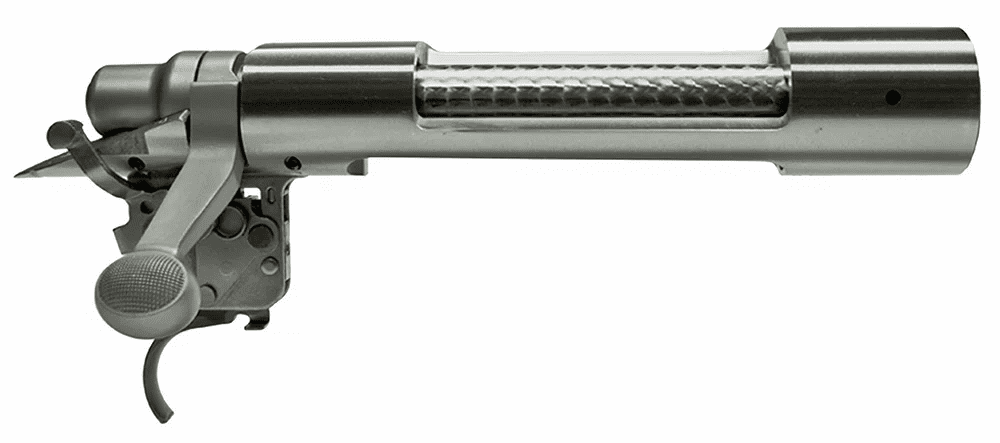

1. Re-cut the face of the action true with the bore

So, what does this mean. The action will be put in a lathe and configured so that it is spinning perfectly true. Truing the action in the lathe means there is no run out in the action. Basically, the action is spinning perfectly on center with no wobble in the work piece. Once this is done the front face of the action/receiver will re-cut so that it is perpendicular to the center bore of the action. This allows the barrel or recoil lug to sit completely flush and straight with the action. We are trying to get the center bore of the action/receiver the same as the center bore of the barrel. The more accurate this center is the more accurate the rifle will shoot.

2. True the lug seats

The seat lugs are the part inside the action that interface with the lugs on the bolt. A rifle bolt will typically have 2 or 3 lugs on it. With the action still in the lathe, the lug seats will also be re-faced so they are perpendicular with the center of the action.

3. True the receiver threads (remove run out from the action)

Typically, factory actions will have run-out in the threads of the receiver. For the barrel to have the best interface with the receiver this run-out or “wobble” in the threads needs to be minimized and removed as much as possible. Run out in factory actions can be .003 to .010 and sometimes even more. This may not seem to be a lot but even thousands of an inch will matter and will be amplified when shooting the rifle particularly at longer distances. If you have the threads re-cut, you will also need to replace the barrel. Since the threads will be cut deeper in this process the old barrel with no longer fit properly. A new match grade barrel is recommended at this point to deliver the best results.

These three steps will greatly improve the accuracy of your rifle. These are typically performed by a qualified gunsmith that is familiar with truing your manufacturer’s rifle.

Once the receiver is complete, we can move onto the actions bolt.

1. True bolt face

The bolt face is the part of the bolt that comes in direct contact with the base of the brass rifle case. With the bolt setup in the lathe and running perfectly true the face of the bolt will be re-cut. This again reduces any inconsistencies that the bolt might have when it comes into contact with the rifle casing.

2. Lapping bolt lugs

In step two of the receiver process the lug seats where re-cut. This process of lapping the lugs on the bolt ensures that each lug makes good contact with the seats when the bolt has been closed. This step should always be done with the trigger installed. Typically, lapping compound is used to remove the high spots on the lug or lugs that are not making good contact.

Having these steps done will greatly improve the accuracy of your rifle. There are other items that can be done to the rifle. It is important to talk with your trusted local gunsmith and have them evaluate the rifle to see what steps they also might recommend.

To talk with 360 Precision about improving the accuracy of your bolt action rifle call 215-399-3598 or email info@360precision.com. We will be happy to discuss the process with you.